Crude Oil Tank Cleaning

Automatic oil tank cleaning systems

Cleaning of Above Ground Storage Tanks (AST), is a vital part of the operations in the oil and petrochemical industries. The cleaning of crude oil and derivative product tanks is required prior to periodic inspection and subsequent mechanical work

Particularly, in cases of larger tanks containing crude oil, or other “black oil” products, such as residue, and heavy gas oils, cleaning of these tanks is a major undertaking that requires a great deal of planning, resources, manpower, time, and expenses. Moreover, the increasingly stringent legislation and regulations regarding environmental protection, safety practices, and operator’s health, have placed additional pressures on the oil and petrochemical industries to utilize safer and more environmentally friendly tank cleaning methods

A large percentage of tanks on a world-wide basis are cleaned with manual or semi-manual methods. Those leave much to be desired because of their low observance of HSE practices, long tank cleaning time, and disposal of large volumes of contaminated matter.

Our BLABO® system cleans tanks with the highest safety, much more quickly, and with recovery of valuable products, which minimizes the disposal of large volumes of pollutants.

The BLABO®

system

Automatic oil tank cleaning system for crude oil, HFO and other black oil tanks

Is the Blabo® system suitable for your tanks?

For difficult-to-clean

tanks such as

Tank capacity

(Up to 1,240,000 bbl)

Tank diameter

(98 – 308+ ft)

Benefits of the BLABO®

technology

Reduced time

- Up to 80% reduction of tank cleaning time (compared to manual)

- Shorter overall tank down-time

Minimal environmental impact

- Minimal waste disposal necessary

- Near 100% recovery of hydrocarbons

- Minimal hydrocarbon emission to atmosphere due to closed-loop cleaning

- Lower consumption of water, electricity and air

Cleaning result

- Unique indexed washing pattern covers complete tank interior surface area

- Re-circulation of cleaning media during desluding

Safe cleaning process

- No staff inside tank during cleaning process (non-man entry system)

- Continuous monitoring and automatic shutdown features

- No risk of explosion

- Minimal health and safety risks to staff

- System complies with ATEX (other standards upon request)

Personal safety

- No staff inside tank during cleaning process (non-man entry system)

- Minimal health and safety risks to staff

- Thorough safety training of operators

Easy maintenance

- No staff inside tank during cleaning process (non-man entry system)

- Continuous monitoring and automatic shutdown features

- No risk of explosion

- Minimal health and safety risks to staff

- System complies with ATEX (other standards upon request)

Follows legislation

Highly flexible

- Modular system can be tailored to customer needs

- Expandable, as customer needs change

Lower costs

How BLABO® works

The BLABO® system for tank cleaning and oil recovery is composed of a number of 20-foot containerised process modules. Depending on the system configuration and the scope of the job, between two to four containerised process modules will be needed.

The modules stand on the ground beside the tank. They contain the equipment required for desludging, recirculating media and separating sludge.

Use the menu at the left to view a brief description of each of the BLABO® modules, including the key components of each module and their individual function within the overall process.

A complete tank cleaning and oil

recovery process

Let us invite you to a BLABO® demontration and see for yourself how the BLABO® system effectively cleans an oil storage tank and simultaneously recovers the oily sludge. Follow the entire process from installation of the BLABO® units, installation of cleaning nozzles, desludgning, washing, oil recovery etc. and on to the final water wash.

Suction module

This module contains pre-filters, a vacuum pump and a centrifugal pump. To optimise the process flow, the unit is situated as close to the tank sump as possible.

The Suction module is used to pump the sludge on to the Recirculation

module and to establish suction from the tank to be cleaned.

Skimming module

Recirculation Module

Seperation module

You may also need auxiliary equipment such as:

Office/ workshop container

Power generator

Air compressor

Inert gas generator

Safety measures

Oreco never compromises on safety in developing its systems. It is our mission to provide the safest, most environmental-friendly tank cleaning system in the world and we constantly develop new features that ensures even safer operation of our systems.

The safety measures in the BLABO® system are not only limited to the design and construction of the system, but also deals with the tank cleaning process and personal safety. The below safety description does not cover all the health, safety and environmental-friendly initiatives that have been found necessary during the risk assessments, but gives you an idea of our dedication to HSE.

Potentially hazardous zones

Complying with standard and directives like ATEX, CSA and UL

Cold tapping

In the BLABO® tank cleaning system and process

Tank cleaning nozzle

BLABO® constructional

Piping

Piping does not fall within the ATEX directive 94/9 because they do not have an own potentially ignition source. However, the user has to ensure that the piping is safely earthed to prevent electro static discharge. The BLABO® system is supplied with Victaulic piping and couplings that can be fitted with clams between each pipe to ensure 100% conductivity.

Pressure piping

All pressure piping is constructed in accordance with the European directive 97/23/EC for pressurized equipment for optimal safety. Fulfilment of this directive includes among other a non destructive test of 10% of all the welding performed by a notified body in accordance with standard EN 13480-4. All pressure piping, valves and fittings are supplied with a unique tracking number and material certificates for optimal personal and environment safety.

Two stage training programe, certification and tests

Customers are by policy trained, examined, and certified

Human health and safety

Non-man entry

Closed loop

Cost /

benefit analysis

As a tank owner or manager, you need to know how much it will cost to clean your tanks. Evaluating the costs of a tank cleaning job usually involves comparing the up-front prices quoted by vendors.

Examinating the total costs of a tank cleaning job illustrates the advantages of automated tank cleaning systems, such as the BLABO® or MoClean® systems.

Overall costs of

manual tank cleaning

Contractor costs:

The quoted price for the tank cleaning job from (external) service provider.

Utility and operating costs:

Consumption of steam, electricity, chemicals, other fuels during cleaning.

Lost production / margin:

Turn-down or shut-down of process units resulting from the temporary loss of capacity while the tank is out of service.

Waste handling / disposal:

Processing of waste streams and disposal of hazardous waste products, both inside and outside refinery.

Legislation and regulations:

Necessary modifications, penalties and fines related to violation of environmental, health and safety regulations.

Mobilization costs:

Construction of scaffolding, crane rental and operation, set-up of cleaning equipment, fresh air systems, high pressure equipment etc.

Re-processing costs:

Cleaned-out sludge and cutter fuel returned to facility may require re-processing.

Internal personnel costs:

Additional operations and maintenance manpower, round-the-clock operation, overtime pay, additional supervision (fire watch, gas watch, safety/work permitting), meals.

Damage to tank interior & internals:

Repair of damages to coating, steam coils and other structures caused by improper tank cleaning procedures.

Personnel liability:

Injuries, illness and loss of life resulting from hazardous working environment and exposure to toxic substances.

Benefits/savings using

Oreco tank cleaning systems

Mobilization costs:

No scaffolding or fresh air systems required. Process modules easily transported and moved using trucks and crane. Assembly of piping between process and tank using safe quick-connect piping.

Re-processing costs:

Fresh crude oil not required. Lower consumption of cutter stock. Separation of sludge into oil, water and solids minimises return of off-specification stocks to the customer.

Internal personnel costs:

Fewer operations and maintenance personnel required in connection with cleaning process. As staff don’t need to enter the tank, there is no need for fire and man-way watches.

Damage to tank interior and internals:

Tank cleaning machines clean effectively with no adverse effects on tank coating, steam coils and other structures.

Personnel liability:

Staff don’t need to enter tank during cleaning. Continuous monitoring of tank atmosphere and automatic shutdown features. Gas detection at process with alarm and shutdown features.

Utility and operating costs:

Construction of scaffolding, crane rental and operation, set-up of cleaning equipment, fresh air systems, high pressure equipment etc.

Lost production / margin:

Faster cleaning process and shorter tank down-time reduces lost production caused by reduced tank capacity.

Waste handling / disposal:

Separation of sludge into oil, water and solids minimizes waste for disposal.

Legislation and regulations:

Systems are designed to comply with present and future environmental, safety and health regulations. Closed-loop systems minimize hydrocarbon emissions to atmosphere.

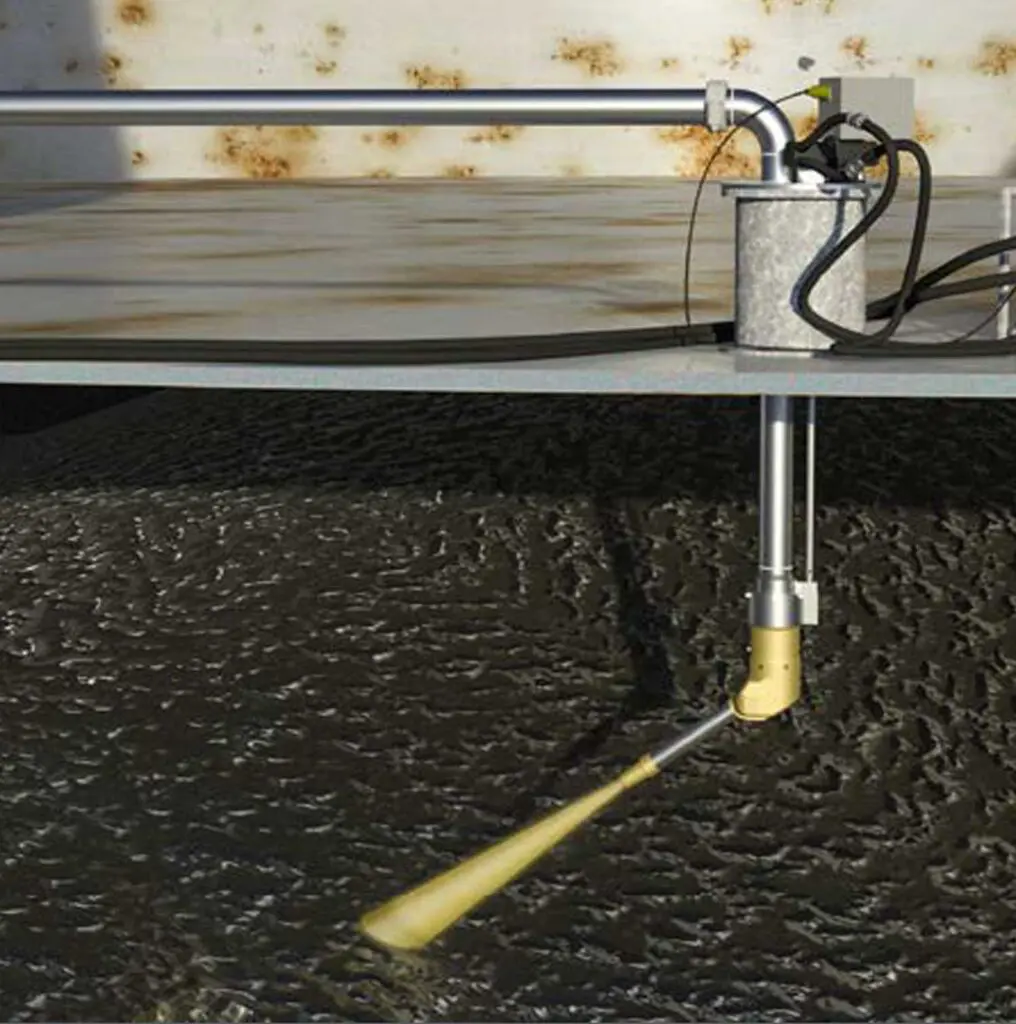

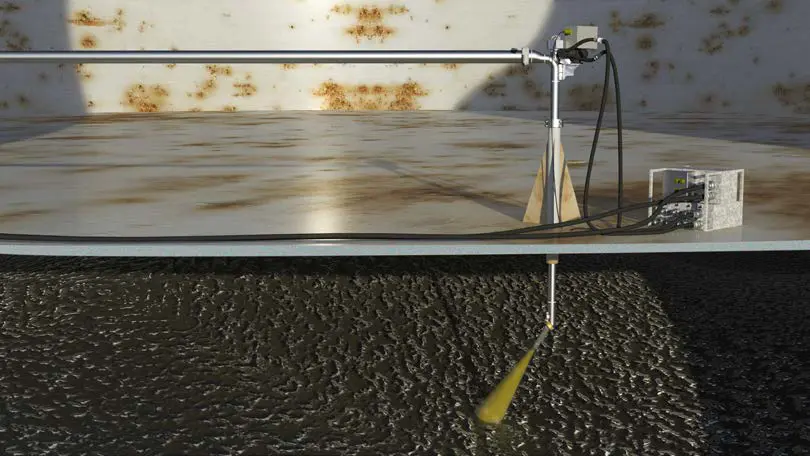

SNS®

Tank cleaning nozzles are an essential element in crude oil tank cleaning.

The Oreco automated non-man-entry systems integrate the unique Oreco SNS® – Nozzles which are specially designed for different tasks or applications. i.e.

- Oreco SNS® – Top Entry – for floating or fixed tank roofs using cold-tapping

- Oreco SNS® – Roof Leg – for floating roofs installed through leg-support sleeves

- Oreco SNS® – Side Entry – for installation on “man-way-holes” of tank walls

Oreco SNS® – Nozzles are the most versatile range of programmable robotic tools to ensure cleaning of tanks with any given complexity or limitations.

The Oreco SNS® brochures

SafeTap®

Making holes (tapping) into tank roofs has always been a major concern to tank owners and tank maintenance contractors. Possibly dangerous situations can arise when drilling or cutting holes in potentially hazardous areas using hot tapping methods.

The ATEX certified SafeTap® is a unique tool that provides a safe, fast and effective method of cold tapping holes in potentially hazardous areas. It is especially suitable for preparing installation of tank cleaning nozzles as part of the Oreco tank cleaning process, and is applicable for use in conjunction with both the BLABO® and the MoClean® systems.

How it works

The SafeTap® tool consists of two main components: a trunk and the cutting instrument. The trunk is placed on a gasket on the tank roof and is securely fastened to the roof by self-drilling screws. Cooling liquid is added during this drilling stage to prevent heat-up of the metal adjacent to the screws. Once the trunk is in place, the cutting instrument is then placed inside the trunk, and the cutting can commence.

Cutting liquid and/or inert gas are added ensuring that no explosive atmosphere can occur. After cutting the hole, the cutting instrument is lifted up and the tank cleaning nozzle is inserted and secured. The trunk remains on the tank roof during the cleaning process.

When the tank cleaning process is completed and the storage tank is ready for hot work, there are two options: The trunk and tank cleaning nozzle can either be removed and replaced by a welded lid, or it can be replaced by a fixed 10″ nozzle according to the construction standards of the tank (e.g. BS 2654 or API 650). Then the tank will be ready for the next cleaning job.

View our SafeTap® movie and see our efficient and safe cold tapping tool in action

Oreco’s SafeTap® is a unique cold tapping tool that provides you with a safe, fast and effective method to cut circular perforations in tank roofs. All stages of the tapping process are performed under cold conditions preventing the risk of ignition that occurs when cutting in metal.

Benefits

No explosive atmosphere can occur when cutting, when the procedure is followed.

After tank cleaning, permanent blind flanges can be installed as per API 653 to prepare the tank roof for future cleaning tasks.

Ensures the most effective cleaning result due to optimal placement of cleaning nozzles

If a fixed 10″ nozzle is left on the tank roof permanently, mobilisation for the next tank cleaning job will take less time.

Cutting one hole can be done in less than 15 minuttes.

The cold tapping procedure is completely safe.

Ensures the most effective cleaning result due to optimal placement of cleaning nozzles